Bullets are an essential component of firearms, serving as the projectile launched towards a target. Understanding what bullets are made of involves examining the materials used, the manufacturing processes, and the historical evolution of bullet technology. This article will delve into the composition of bullets, tracing their history from ancient times to the present day, and exploring modern advancements in bullet design.

Historical Context

Early Innovations

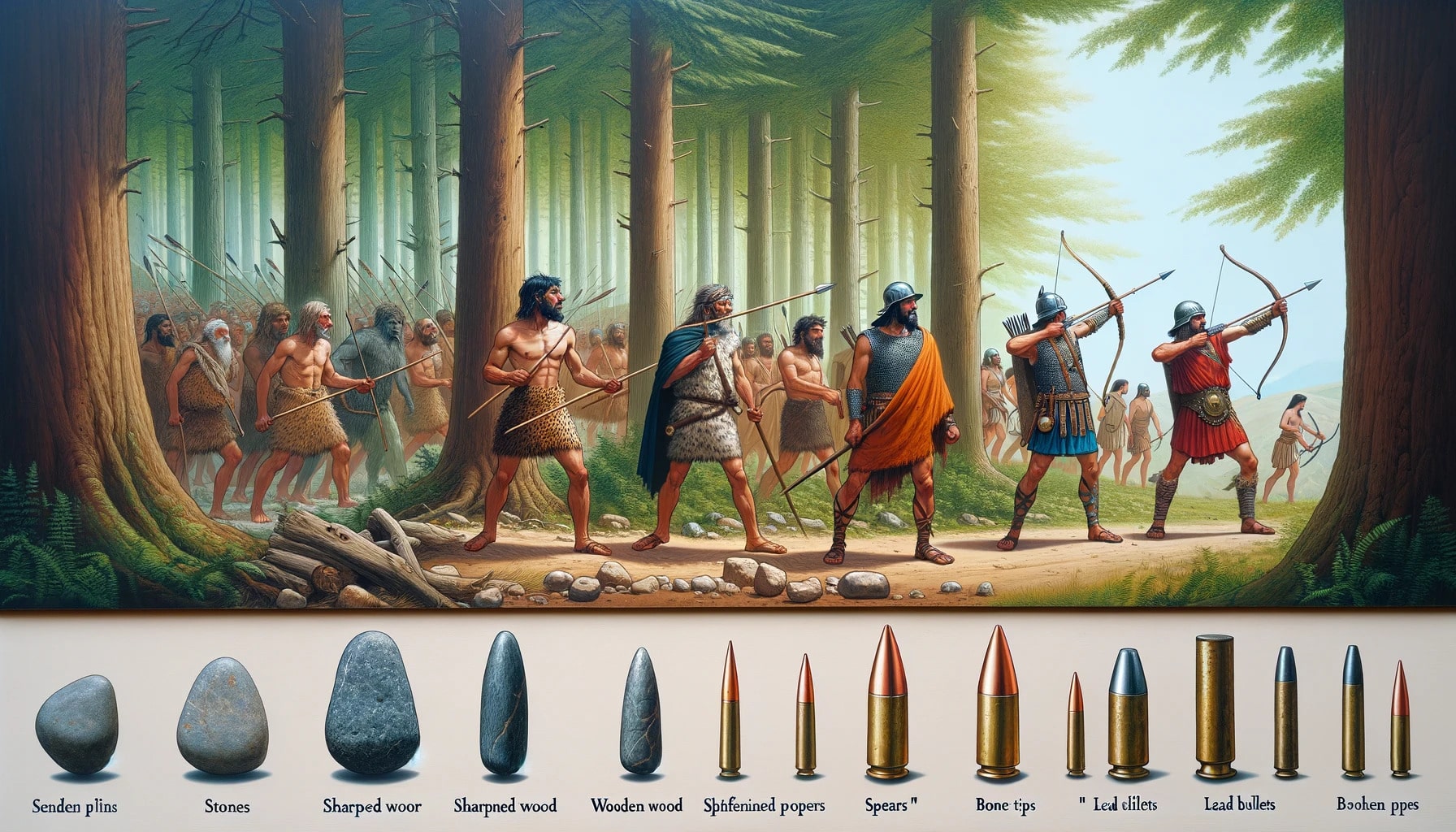

The concept of launching projectiles can be traced back to ancient civilizations. Early bullets were often made from materials readily available to their creators.

- Stone and Lead: In prehistoric times, stones were the primary projectiles used in slings and primitive weaponry. As metallurgy advanced, lead became the material of choice due to its malleability and density. Ancient Greeks and Romans crafted lead bullets, known as "sphendone," for use in their weapons.

- Wooden and Bone Projectiles: Before metal, some cultures used sharpened wooden or bone projectiles for hunting and warfare. These materials were simple to fashion and available in most environments.

The Birth of Modern Ammunition

The invention of the firearm in the 15th century transformed bullet design and manufacturing. The early bullets were simple lead balls, often called "round balls." These were relatively effective but lacked aerodynamic properties.

- Minié Ball: In the mid-19th century, the Minié ball, a conical bullet with a hollow base, revolutionized ammunition. It was more accurate than round balls, leading to its widespread use in rifled muskets.

- Copper and Brass Jackets: By the late 19th century, bullets began to be jacketed in copper or brass. This innovation helped improve the bullet's performance by reducing barrel fouling and enhancing aerodynamic efficiency.

Composition of Bullets

Modern bullets consist of multiple components, each serving a specific purpose. The primary materials used in bullet manufacturing include:

1. Lead

Lead is a dense metal commonly used as the core of many bullets. Its weight aids in delivering significant kinetic energy upon impact. However, concerns about lead's toxicity have led to the development of alternative materials.

2. Copper and Brass

Copper and brass are often used for bullet jackets. These materials provide several benefits:

- Reduced Barrel Fouling: Copper jackets prevent lead from depositing in the gun barrel, ensuring consistent performance.

- Improved Aerodynamics: The smooth surface of copper jackets enhances the bullet's aerodynamic properties, contributing to better accuracy.

3. Polymer

Modern bullets sometimes incorporate polymer materials, particularly in hollow-point designs. Polymers can reduce weight and alter the bullet's expansion characteristics upon impact.

4. Steel

Steel-core bullets are gaining popularity for specific applications. They are typically found in armor-piercing ammunition due to their hardness and durability.

Types of Bullets

Bullets come in various shapes and sizes, each designed for specific applications. The most common types include:

1. Full Metal Jacket (FMJ)

FMJ bullets feature a lead core encased in a copper or brass jacket. They are known for their ability to penetrate targets without deforming, making them popular for military and practice ammunition.

2. Hollow Point (HP)

Hollow point bullets are designed to expand upon impact, creating a larger wound channel. This type is favored for self-defense and hunting due to its stopping power.

3. Soft Point (SP)

Soft point bullets have an exposed lead tip that facilitates controlled expansion. They are often used for hunting, providing a balance between penetration and expansion.

4. Boat Tail

Boat tail bullets have a tapered rear end, improving their ballistic performance. They are commonly used in long-range shooting applications.

5. Armor-Piercing (AP)

Armor-piercing bullets feature a hardened core, often made of steel or tungsten. These are designed to penetrate armor and are subject to strict regulations.

Advances in Bullet Technology

As of 2024, bullet technology continues to evolve. Manufacturers are focused on improving performance, accuracy, and safety. Notable advancements include:

1. Lead-Free Bullets

With increasing awareness of lead's environmental impact, many manufacturers are developing lead-free alternatives. These bullets often utilize copper, polymer, or other materials to achieve performance comparable to traditional lead-based bullets.

2. Enhanced Ballistics

Advancements in materials science have led to the development of bullets with improved ballistic coefficients. These bullets offer better performance over long distances, making them ideal for competitive shooting and hunting.

3. Smart Bullets

Emerging technologies are exploring the concept of "smart bullets" equipped with sensors and guidance systems. Although still in experimental phases, these bullets have the potential to enhance accuracy and targeting precision.

4. Specialty Bullets

Modern manufacturers are producing specialized bullets for niche applications, such as frangible bullets designed to disintegrate upon impact with hard surfaces, reducing the risk of ricochet.

Conclusion

Bullets have come a long way from their early origins as simple stone projectiles. The materials and technologies used in their construction have evolved significantly, driven by advancements in metallurgy, materials science, and ballistics. Understanding what bullets are made of not only provides insight into their functionality but also highlights the ongoing innovations in the field of ammunition. As we move forward, it will be fascinating to see how bullet technology continues to evolve, balancing performance with environmental considerations.